- Main

- Products

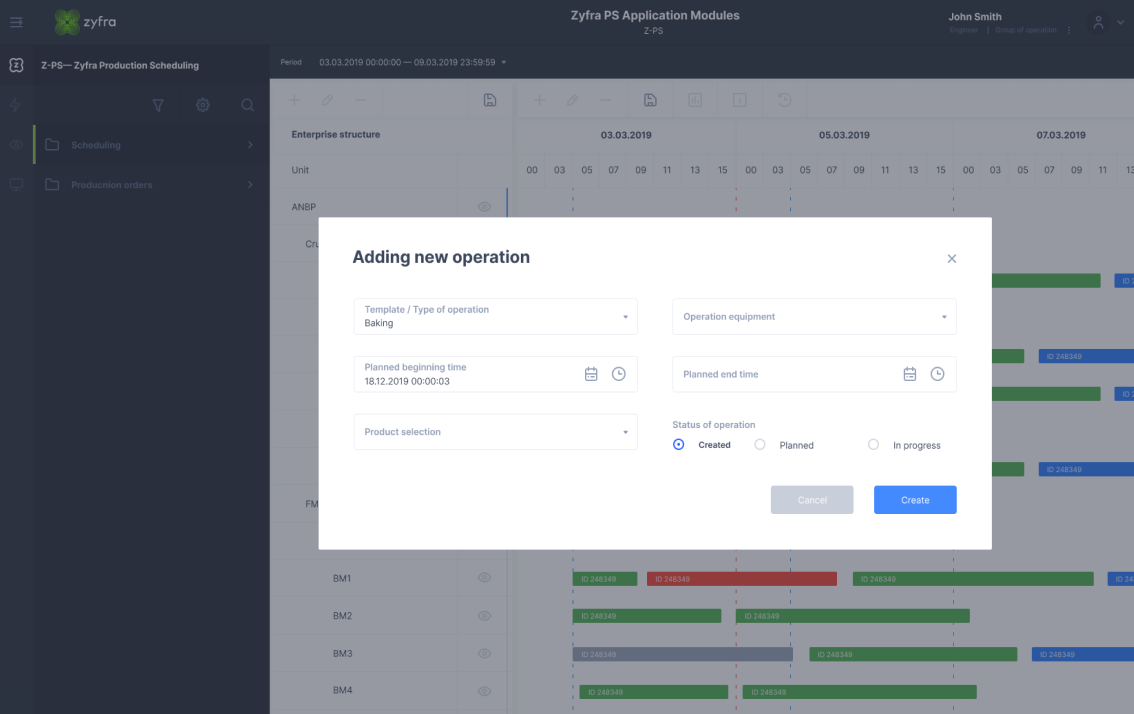

- Zyfra Production Scheduling

Zyfra Production

Scheduling

Features

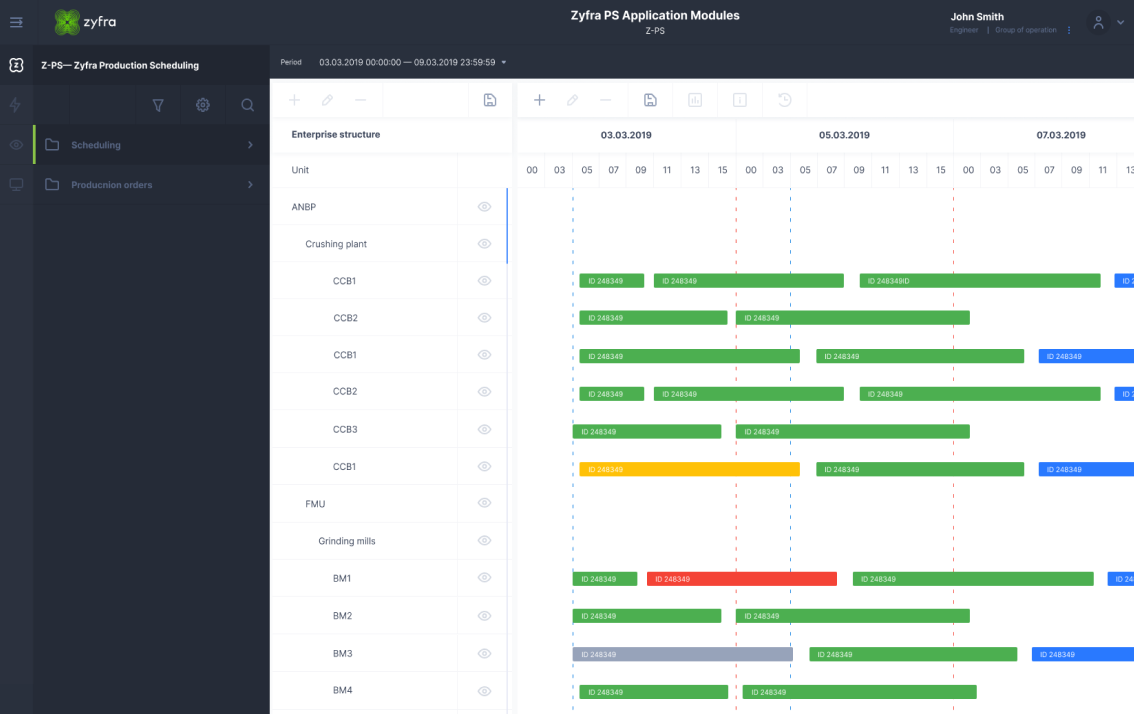

Modelling production processes and resources to solve specific production problems

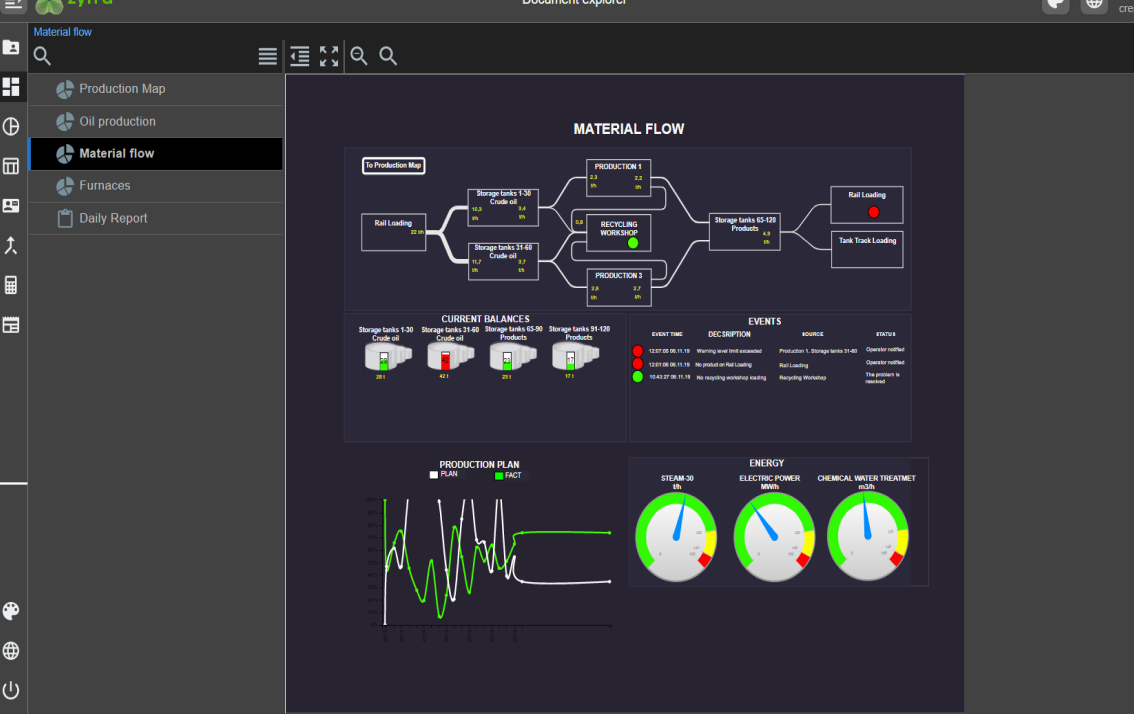

Transforming production data into information relevant to all specialists and managers involved in production

End-to-end production chain tracking of the finished product

Improving efficiency for technical equipment usage, energy, material, and other production resources

In today’s production world it’s all about producing more, faster and cheaper while cutting losses and maintaining quality standards. Zyfra Production Scheduling can help your enterprise with all that and put more control over your operation into your hands and the hands of your specialists, managers and engineers.

It’s all about improving efficiency, constant monitoring and identifying potential problems, before they can interrupt production. Production Scheduling is unique in that it provides a company with various applied solutions, which meet modern business requirements, in a short time and at minimal cost.

© 2024 All Rights Reserved. Zyfra.

Privacy Policy.